3D printing is a highly versatile technology with a wide range of methods, materials, and applications. The cost of 3D printers varies greatly, from affordable models priced in the few hundred-dollar range to high-end printers that can cost over a million dollars. The price is often determined by advanced proprietary or patented technology and features that enable faster and higher-quality printing without requiring extensive technical expertise.

Interestingly, the size of the printer does not necessarily dictate its cost. Some of the most expensive 3D printers utilize cutting-edge technologies, such as multiple high-powered lasers for metal sintering or photonic curing of liquid resin to create extremely precise and intricate objects at a microscale.

It’s worth noting that not all expensive 3D printers are available for purchase. Some are offered through subscription models, making them more accessible and affordable, while others are rented on a project basis, typically with operators available to oversee the printing process. Carbon 3D is an example of a company that offers printers through a subscription model, while Icon 3D’s Vulcan construction printer is available for hire on a project basis, specifically for large-scale construction projects.

The field of 3D printing continues to evolve, and new technologies and models are constantly being introduced to the market. The cost of 3D printers can vary depending on the specific requirements and capabilities needed for different applications, making it important to consider the specific needs and budget when selecting a 3D printer.

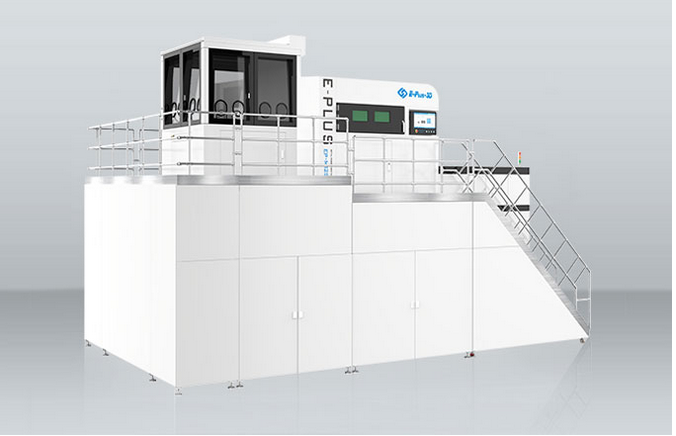

EPlus3D EP-M1250

EPlus3D, a China-based company, specializes in manufacturing large-scale metal 3D printers to meet the demanding needs of the country’s manufacturing industry. These printers are utilized in various sectors including aerospace, automotive, electronics, and tooling. They are capable of producing not only massive parts like molds for heavy industry but also mass-produced components.

One of EPlus3D’s flagship models is the EP-M1250 metal 3D Printer. This printer boasts an impressive build volume of 1,258 × 1,258 x 1,350 mm. It utilizes metal powder and incorporates nine lasers to achieve a remarkable 99.9% density in the produced metal parts. The printer is compatible with a wide range of materials and can achieve a printing speed of 240 cm³ per hour.

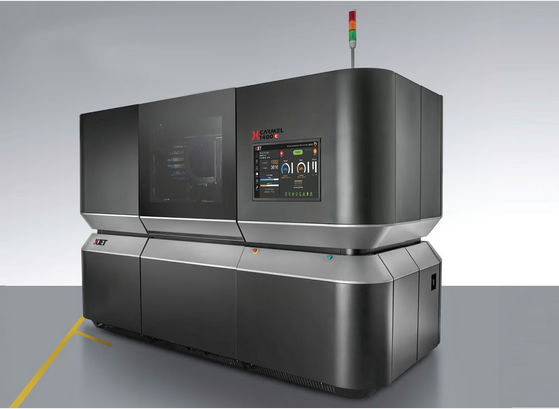

XJet Carmel 1400C

XJet, an Israel-based company, has pioneered a distinctive and high-priced ceramic 3D printing technology known as NanoParticle Jetting (NPJ). This technology enables the production of metal and ceramic parts with exceptional detail, surface finish, and accuracy. The printer’s value is not solely attributed to its advanced technology and proprietary materials but also to the sophisticated automation integrated into the printer, making it user-friendly.

The XJet Carmel 1400C printer boasts an expansive 1,400 cm² build tray, which is one of the largest in the industry. This substantial build tray allows for the simultaneous production of multiple ceramic parts, enhancing efficiency and productivity.

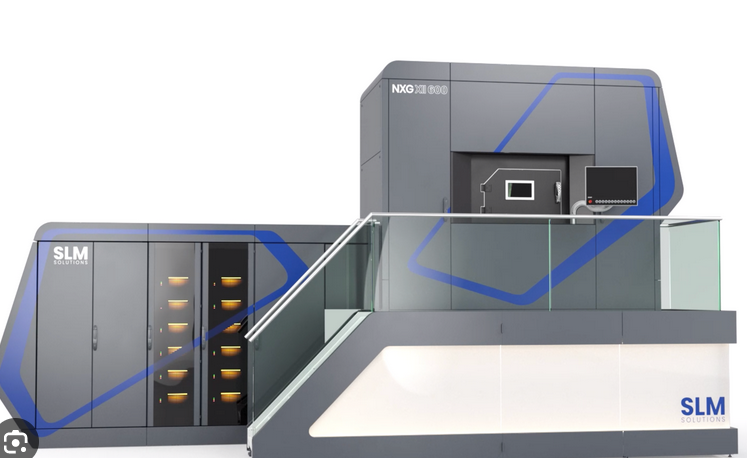

SLM Solutions NXG Xll 600

of printers. However, their NXG XII 600 is positioned as a revolutionary product for industrial manufacturing. This printer is specifically designed for high-volume, serial production applications and incorporates cutting-edge features.

The NXG XII 600 stands out with its industry-first configuration of 12 lasers, each operating at 1,000 Watts. This laser system provides unprecedented speed and throughput, surpassing what is typically available in a single machine.

In addition to its advanced laser technology, the NXG XII 600 includes a comprehensive set of features requested by SLM Solutions’ manufacturing customers over the years. These features include automatic build start, laser focus function, closed powder system, and various other developments aimed at optimizing the printing process and ensuring high-quality results.

UpNano NanoOne Bio

UpNano, an Austria-based company, has made significant advancements in 3D printing technology with their development of a two-photon 3D printer and a hydrogel-based bioink. This breakthrough allows for the direct printing of 3D structures containing living cells at both the meso- and microscale.

The NanoOne Bio printer is part of UpNano’s NanoOne series of laser-powered printers, offering the ability to fabricate structures across an impressive 12 orders of magnitude. This versatility opens up a wide range of possibilities for various applications.

The key innovation lies in the development of the hydrogel-based bioink, called X Hydrobio INX U200, which is the only commercially available resin capable of embedding living cells directly from a culture plate into 3D printed structures for biological applications. This advancement enables biomedical research and development in both industry and academia, empowering pharmaceutical companies and research institutions to design cell models that closely mimic the natural growth conditions found in the human body.

Black Buffalo

Black Buffalo 3D, a US-based company backed by South Korean investors, recently introduced its Nexcon 1G concrete construction 3D printer. This printer is specifically designed for constructing houses and other large concrete structures. One notable feature is its ability to complete a 1,000 square-foot building in less than 20 hours.

The Nexcon 1G utilizes Black Buffalo’s proprietary cement material, referred to as ink, which can be customized and colored to match specific environmental conditions such as temperature, humidity, and altitude.

This modular 3D construction printer, known as the Nexcon 1G, can be expanded in the X, Y, and Z axes to accommodate projects of various sizes, with a maximum height of up to three stories. A unique aspect of the printer is its ability to reposition the base tracks, allowing users to move the printer to a new print area without dismantling the X or Z axis components. This flexibility enhances convenience and efficiency during the construction process.

Optomec LENS 860

Optomec, a US-based company, specializes in directed energy deposition (DED) metal 3D printing technology. This innovative technology allows for the repair of oversized titanium components commonly found in aircraft engines. Optomec offers a range of 3D printers, including the LENS 860 Machine, which are specifically designed for metal additive manufacturing and hybrid manufacturing processes.

The LENS 860 Machine tool systems are well-suited for building, repairing, or coating mid- to large-size metal parts. These printers offer larger build volumes and higher power capabilities, enabling the production of complex and durable metal components. With Optomec’s DED technology, manufacturers can achieve precise and efficient metal 3D printing for a variety of applications.

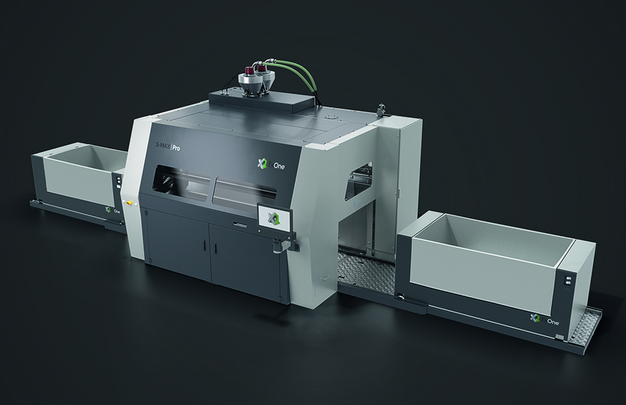

ExOne S-Max Pro

ExOne, now owned by Desktop Metal, offers a range of printers that are known for their affordability and impressive capabilities. However, their large format sand printers are on the higher end of the price spectrum.

These sand printers are specifically designed for creating intricate and detailed sand molds and cores used in metal foundries for industrial applications. One notable model is the S-Max Pro, which boasts a generous 1,260-liter build box, making it ideal for rapid product development and reliable production of sand molds and cores. The fully automated printhead enhances print speed, while advanced powder compaction technology ensures excellent green density and strength, even for complex designs.

As the most advanced system in the ExOne family of 3D sand printers, the S-Max Pro is geared towards continuous 24/7 production. It offers integration with Industry 4.0 technologies, including cloud connectivity and real-time machine monitoring, facilitating seamless production processes and efficiency. While these large format sand printers come with a higher price tag, they deliver exceptional performance and capabilities for industrial-scale sand mold and core production.