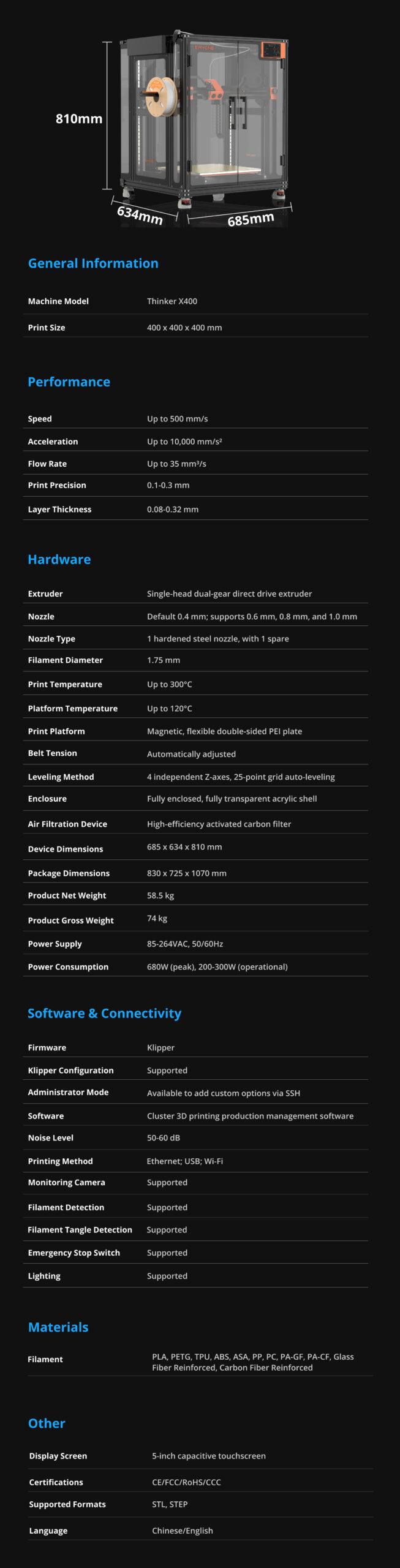

Welcome to the world of the Eryone Thinker X400, meticulously crafted for professional print farms. This innovative 3D printer redefines industry standards with its expansive functionality, precision engineering, and advanced technology.

-1024x340.jpg)

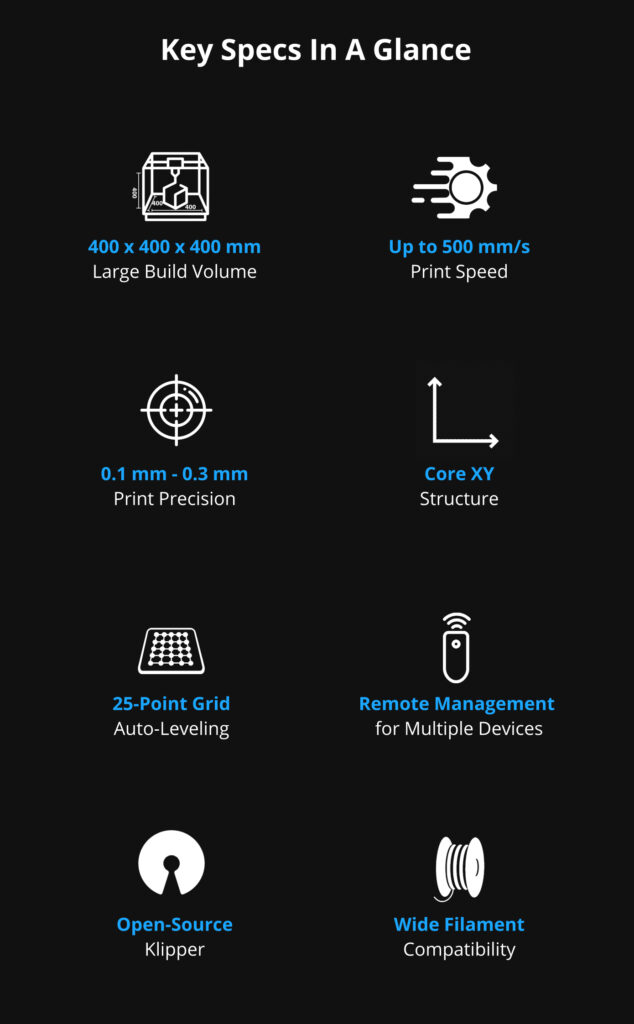

The Thinker X400 is tailored for professional and production use, offering significant advantages over consumer-grade printers. With a build volume of 400 x 400 x 400 mm and print speeds up to 500 mm/s, it excels in handling larger projects quickly. Its all-metal frame and Core XY design reduce vibrations, ensuring high precision levels of 0.1-0.3 mm.

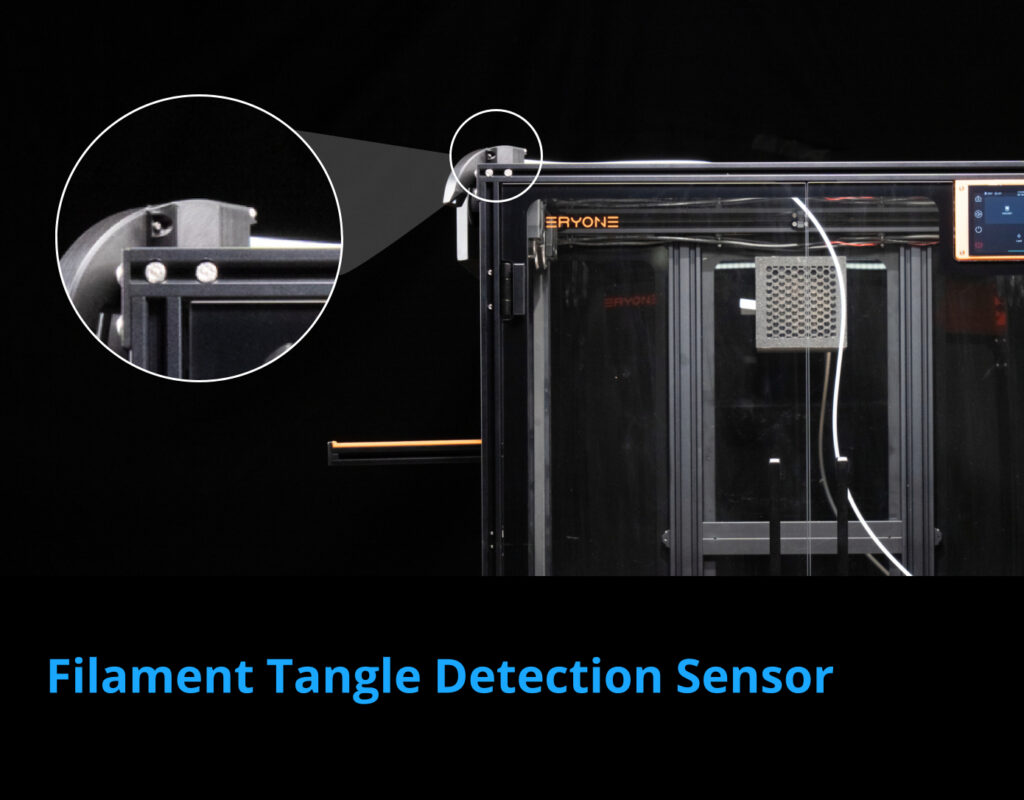

The X400 supports advanced materials, including carbon fiber reinforced filaments, and features like automatic bed leveling, automatic Z offset, filament detection, filament tangle detection, and real-time monitoring—capabilities typically lacking in consumer models. Overall, the X400 delivers superior quality and reliability for demanding 3D printing applications.

-1024x95.jpg)

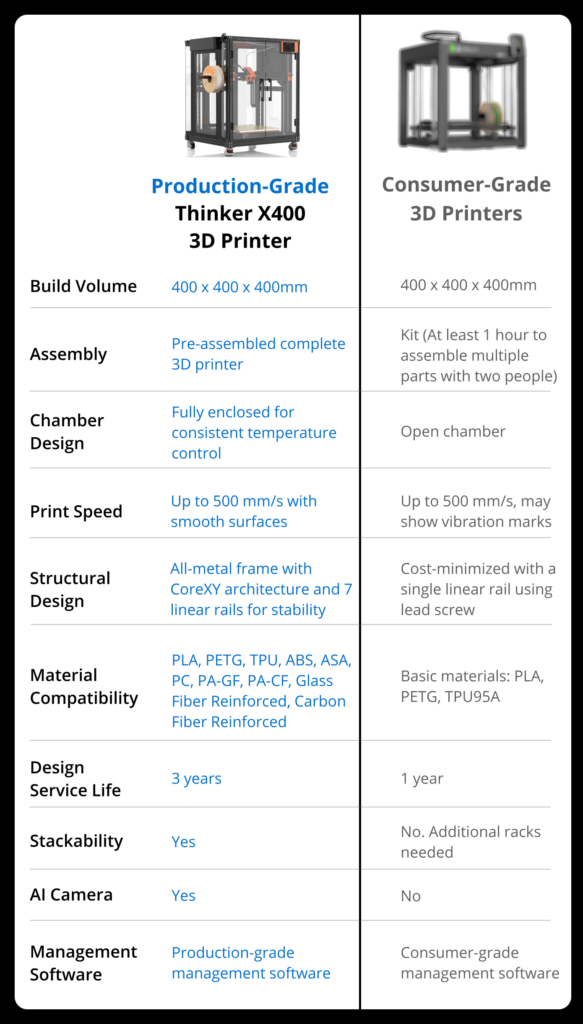

With a substantial build area of 400 x 400 x 400 mm, the Thinker X400 allows you to create large models that meet the demands of even the most intricate designs and multi-part projects.

The large volume accommodates a wide variety of projects—from sizable prototypes and functional parts to intricate architectural models—making the Thinker X400 suitable for industries like engineering, design, education, and art.

-1024x95.jpg)

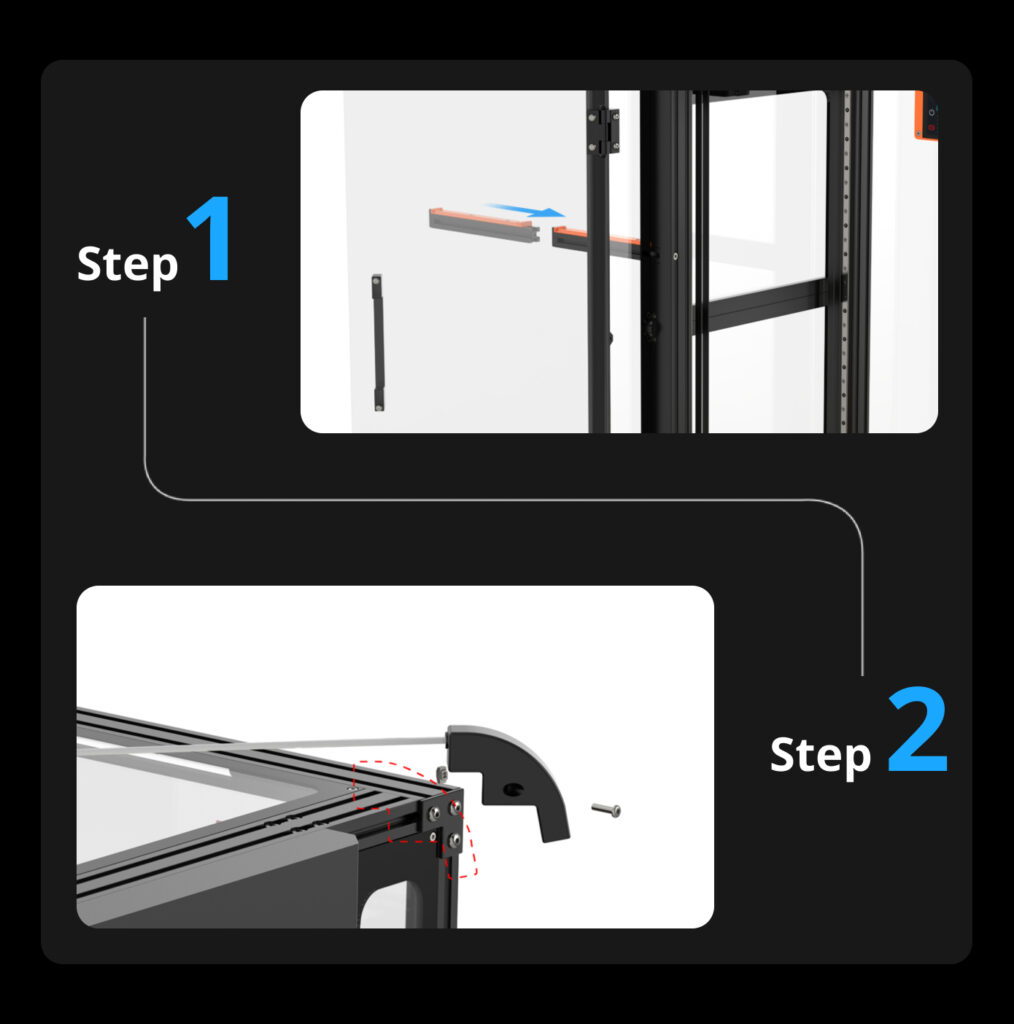

The Thinker X400’s fully enclosed acrylic design ensures stability and safety when stacked in printing farms. It maintains optimal printing temperatures, safeguarding precision in every part.

- Ultra-Fast Printing up to 500 mm/s Achieve remarkable print speeds without compromising quality. With the ability to print up to 500 mm/s, you can complete projects in a fraction of the time it would take with standard printers.

- Exceptional Acceleration of 10,000 mm/s² The printer’s high acceleration enables it to reach top speeds almost instantly. This reduces the idle time between movements, especially beneficial for complex designs with numerous directional changes.

- High Flow Rate of 35 mm³/s A maximum flow rate of 35 mm³/s ensures consistent and efficient material extrusion at high speeds. This maintains print integrity and surface quality, even when operating at maximum velocity.

-598x1024.jpg)

-1024x800.jpg)

-1024x95.jpg)

Equipped with a dual-gear single-head direct-drive extruder and a default 0.4 mm nozzle, the Thinker X400 supports nozzle sizes of 0.6mm, 0.8mm, and 1.0mm, enabling high-quality prints with a wide range of materials.

- Quick-Release Nozzle The Nozzle comes with a quick-release mechanism for effortless maintenance. By simply loosening three screws, you can remove and replace the nozzle without disconnecting the heating pad or thermistor wiring harness. This makes replacements easier and allows for tighter fastening to the heating block, enhancing heating efficiency.

- Improved Extrusion The enhanced extruder delivers smoother and more consistent material flow, reducing the risk of blockages. This ensures even filament distribution, resulting in perfect prints with impeccable detail and surface quality.

- Enhanced Melting Designed to heat filament more efficiently, the extruder reaches temperatures of up to 300°C with a heating power of 70W and a maximum flow rate of 35 mm³/s. This accelerates the melting process while maintaining precise temperature control, accommodating a wide range of filament types for versatile printing options.

-1024x95.jpg)

The Thinker X400 features a Core XY structure with high-quality linear guides, providing stable and precise movement. This design allows for faster acceleration and reduced moving mass compared to a Cartesian system, where each axis operates independently. As a result, vibrations are minimized, ensuring smooth motion of the print head and consistent layer alignment.

- Robust All-Metal Frame The entire machine is constructed with an all-metal profile frame, making it exceptionally sturdy, reliable, and durable. This solid build ensures overall stability, reduces vibrations during printing, and contributes to higher print accuracy and quality.

- Strong Resistance to External Interference Designed to withstand external disturbances, the Thinker X400 maintains consistent performance even in challenging environments. This resilience ensures reliable printing without unexpected interruptions or errors caused by environmental factors.

-1024x95.jpg)

Integrating an efficient cooling system above the extruder with three 4010 fans that provide full wrap-around airflow, the Thinker X400 boasts high-performance thermal management. This steady and directed airflow rapidly solidifies each layer immediately after printed, minimizing warping and results in cleaner, more detailed prints.

-1024x95.jpg)

The Thinker X400 is equipped with an advanced 25-point grid auto-leveling system, complemented by four independent Z-axes. By automatically calibrating the print bed’s surface, the X400 minimizes the risk of adhesion issues and warping, enhancing overall print quality. At the same time, it streamlines your process.

- Extruder with Physical Contact Sensor Equipped with a physical contact sensor, the extruder head directly detects the surface of the printing platform. This direct sensing allows for precise measurements, eliminating guesswork and manual adjustments.

- Advanced Algorithms for Full Automation Combined with Eryone self-developed algorithms, the system achieves fully automatic leveling. This means you spend less time setting up and more time printing, with the confidence that your first layer will adhere perfectly.

- XY-Axis 4-Point Automatic Leveling This feature precisely calibrates the horizontal plane using four strategic points across the XY-axis. It ensures that the print bed is level from corner to corner, reducing the risk of print failures due to uneven surfaces.

- Z-Axis 25-Point Automatic Leveling Fine-tuning the vertical axis, the system analyzes 25 distinct points along the Z-axis. This meticulous calibration optimizes layer adhesion and results in flawless print quality, even for intricate or large-scale projects.

-1024x95.jpg)

The extruder head is equipped with a wear-free, bearing-rolling photoelectric sensor that precisely monitors the filament status. When the filament runs out or becomes excessively thin, the system immediately detects the issue and halts the printing operation to prevent “air printing” and wasted material, ensuring timely intervention without causing wear to the filament itself.

Additionally, the system is designed to be friendly to soft TPU materials, allowing you to print TPU filaments with a hardness below 95A effortlessly. This compatibility expands your material options and enables the creation of flexible and durable prints. By integrating this advanced detection technology, you can maintain consistent print quality, reduce material waste, and expand your creative possibilities.

-1024x95.jpg)

Eryone’s AI Camera system provides remote monitoring of each printer’s status for convenient oversight. The camera integrates advanced image recognition technology to detect any foreign objects or unremoved prints on the printing platform before a new print job begins.

This proactive detection effectively prevents nozzle collisions and potential damage to the printer, ensuring a smooth and safe printing process. With the ability to monitor and manage printers remotely, you gain peace of mind and efficiency, especially when overseeing multiple units or managing printers in different locations.

-1024x95.jpg)

Remove prints with ease with the Magnetically Flexible Double-Sided PEI (Polyetherimide) Build Plate. The PEI surface provides excellent adhesion during printing, ensuring your model stays firmly in place. Once printing is complete, simply flex the magnetic build plate to effortlessly release your print.

The double-sided design extends the plate’s lifespan, and the magnetic attachment allows for easy installation and removal, streamlining your workflow and enhances overall printing efficiency.

-1024x95.jpg)

The Thinker X400 features a responsive 5-inch touchscreen that provides an intuitive interface for easy navigation and control. With clear visuals and user-friendly menus, you can quickly adjust settings, start or pause prints, and monitor progress all from a single device.

-1024x95.jpg)

The Thinker X400 supports a wide range of filaments, providing you with the flexibility to tackle diverse projects. Compatible materials include: PLA, PETG, ABS, ASA, TPU, PA (glue assistance required), PP (glue assistance required), and various carbon fiber composites like PLA-CF, PETG-CF, ABS-CF, PA-CF, ASA-CF, PET-CF, and more. This extensive material compatibility enhances the diversity and creativity of your printing projects.

-695x1024.jpg)

-1024x95.jpg)

Equipped with carbon air filters, the Thinker X400 enhances air quality during the printing process. It captures and neutralizes harmful particles and odors released during the printing process, especially when working with filaments like ABS that emit fumes. Ensuring effective air purification makes the printer ideal for use at home, in studios, or in office settings, keeping your workspace pleasant and free from irritants.

-1024x95.jpg)

Thanks to the full enclosure design, the Thinker X400 operates at a noise level of just 50-60 dB, ensuring a quieter printing environment. This reduction in noise allows you to work comfortably without distractions, making it ideal for both home and professional settings.

-1024x258.jpg)

The X400 is equipped with advanced 3D printing production management software that enables seamless networking and management of multiple devices. This feature greatly simplifies the mass production process, making operations more convenient and efficient.

-1024x800.jpg)

- Bulk Actions for Efficient Printer Management Effortlessly manage printers with the Bulk Actions feature. With just a click, you can send printing task to multiple printers simultaneously, ideal for large-scale printing operations, streamlining your workflow.

- Remote Printing for Ultimate Convenience Experience the freedom of managing and monitoring your 3D printing projects from anywhere with our Remote Printing feature. Thanks to smart wireless connectivity, you can start, pause, or adjust your prints remotely using your smartphone or computer.

- 3D Print Job Queue for Maximized Efficiency Boost efficiency in large-scale 3D printing setups with our 3D Print Job Queue feature, integrated into our farm production management software. This intelligent system allows simultaneous management of multiple printers, optimizing production through automated queuing. Schedule multiple print jobs in advance to minimize downtime and ensure smooth, continuous operation—perfect for print farms or high-demand production environments.

-1024x95.jpg)

-300x169.jpg)

-1024x167.jpg)

-1024x167.jpg)

-616x1024.jpg)